Track inspection approvals

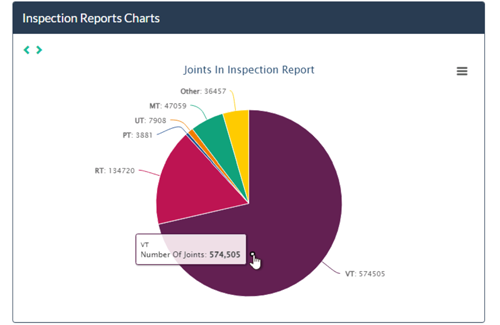

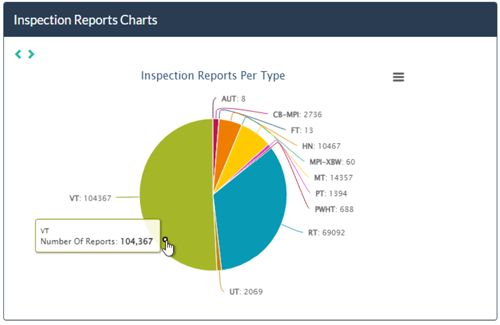

Create and track NDE Inspection Reports for various types (RT, PT, MT, etc.) and keep track of joint approvals and rejections within these reports.

Include reasons for approvals/rejections, defect types and measurements, and upload supporting photos.

Easily share and access NDE reports with all details included to streamline handover and test packages.

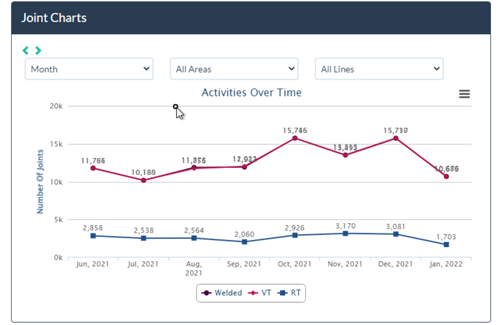

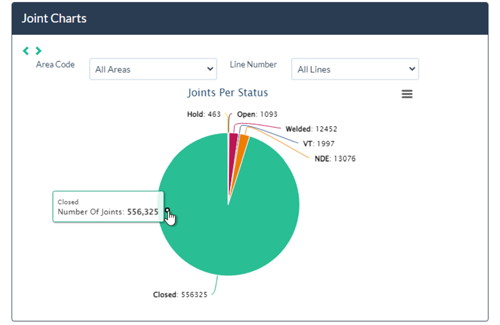

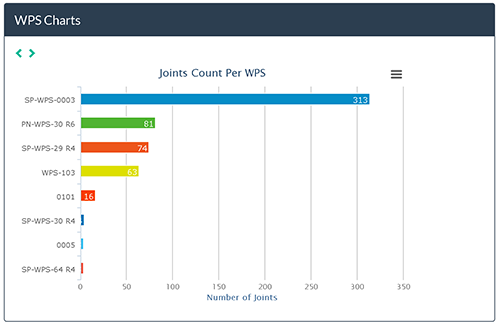

Better decision making

Utilize project welding data to gain insight into progress, and allocate resources and focus team efforts on areas that require the most attention.

Proactively identify and address potential handover issues by structuring and completing reporting in advance.

Welding standards

Adhere to various welding codes and standards such as ASME, AWS, API, EN, etc.

by utilizing built-in validations within Welding Manager© that cover code requirements such as rejection penalties, thickness and diameter ranges, and certifications.

Achieve your quality targets

Achieve client quality objectives by structuring welding data in a centralized platform using Welding Manager©.

Give clients access to the system and control what progress reports they can view, thus reducing lag time for reporting on project status.

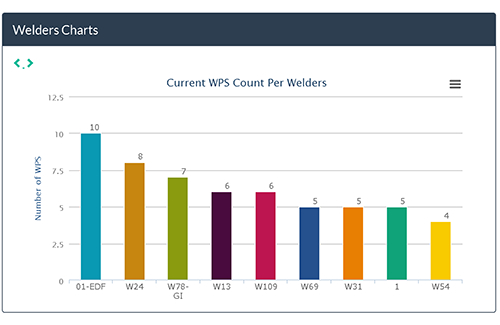

Monitor welders' performance

Track welders' productivity, production joints, rejection rates, status, availability, and WPS qualifications using Welding Manager©.

Create a welder profile with complete history and record details.

Track NDT progress

Verify compliance with required percentages for Radiographic Testing reports (RT%) and other NDT report types by tracking them by Piping Class, Line, Tank, Type, Systems, and Area using the Welding Manager©'s reports and dashboard key performance indicators (KPIs).

Documentation

Efficiently structure client reporting and welding documentation by customizing reporting templates within the system and directly exporting them to avoid delays in report preparation.

Balance your workload

Generate task-specific reports (requests) such as Fit-up, Weld, and Paint, etc.

Include a list of joints that need to be handled in the request and assign it to the appropriate teams.