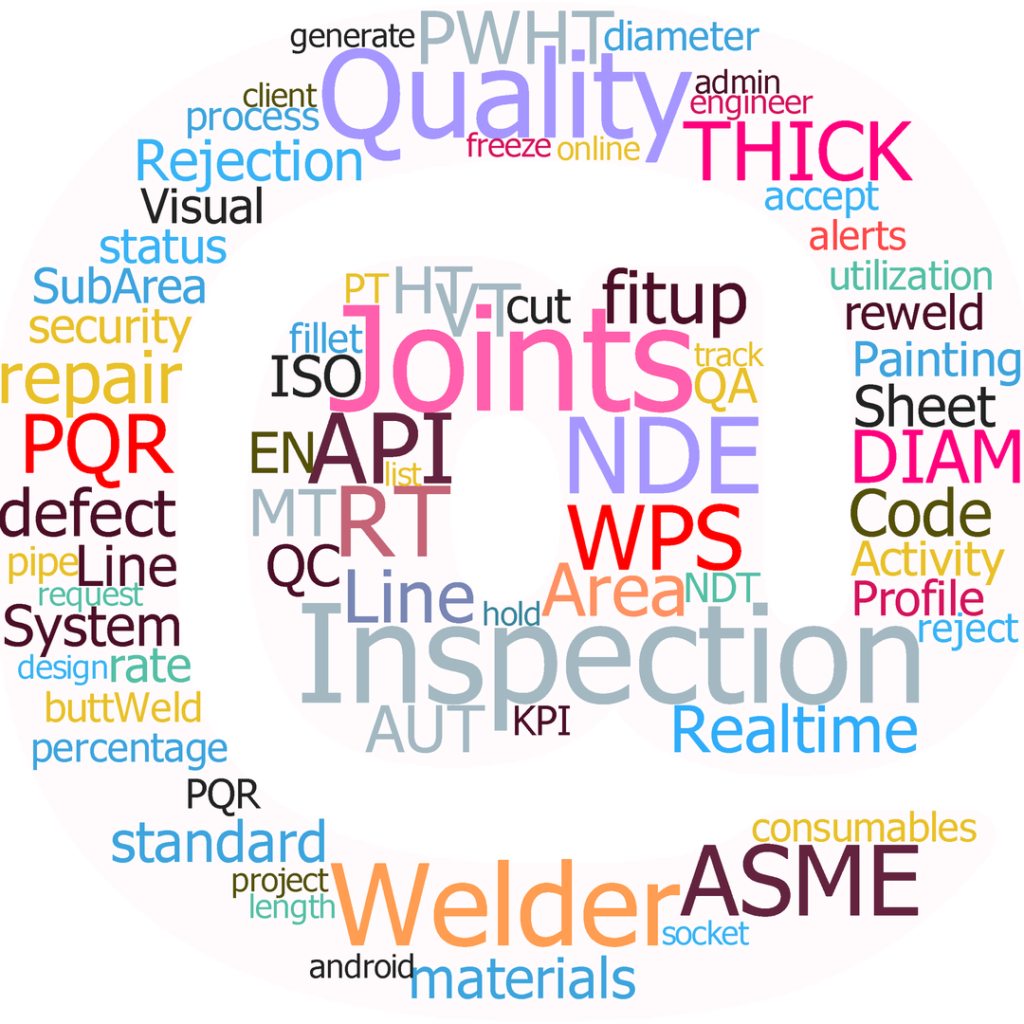

Welding is a critical aspect of many industries, from construction and manufacturing to shipbuilding and repair. However, ensuring that welders are qualified and that their work meets industry standards can be a challenge. One way to improve the qualifications of welders and the quality of inspection reports is to use Welding Manager© software, in combination with Non-Destructive Examination (NDE) techniques.

Welding Manager© software is a solution that helps companies manage and track the qualifications of their welders. It allows managers to easily view and update information about welders, such as their certifications, training records, and experience. The software also helps managers track the progress of welding projects, including the type and location of each weld and the qualifications of the welder who performed it.

On the other hand, NDE is a set of techniques that allow the inspection of materials and structures without causing any damage. NDE techniques include Radiography, Ultrasonics, Magnetic particle, Liquid penetrant, Visual, and others. These techniques are used to detect and evaluate defects in materials and structures, making it possible to identify and correct issues before they become more significant problems.

By combining the use of Welding Manager© software and NDE techniques, companies can ensure that their welders are qualified to perform the work they are being asked to do and that their welding work meets or exceeds industry standards. For example, if a welder does not have the necessary certifications or training, the software will flag this, and the manager can take steps to ensure that the welder receives the appropriate training before proceeding with the project. Additionally, NDE can be used to perform inspections on the completed welds to detect and evaluate any defects that may have occurred during the welding process, thus improving the quality of inspection reports.

Welding Manager© software can also be used to generate detailed reports that can be used to demonstrate compliance with industry standards and regulations. These reports can be used to demonstrate to customers, regulators, and other stakeholders that the company’s welding work meets or exceeds industry standards.

In summary, Welding Manager© software in combination with NDE techniques, is a valuable tool for companies that want to improve the qualifications of their welders and the quality of their inspection reports. By using this combination, companies can ensure that their welders are qualified to perform the work they are being asked to do, improve the quality of their inspection reports, and demonstrate compliance with industry standards and regulations.

Check our website for more info https://www.weldingmanager.com

Leave a Reply